Reliability Marketplace

Failure Modes to Failure Codes - Digital Version - E-Book

Failure Modes to Failure Codes - Digital Version - E-Book

SKU:by John Reeve and Derek Burley, 107 pages

Couldn't load pickup availability

Written by John Reeve and Derek Burley, 107 pages

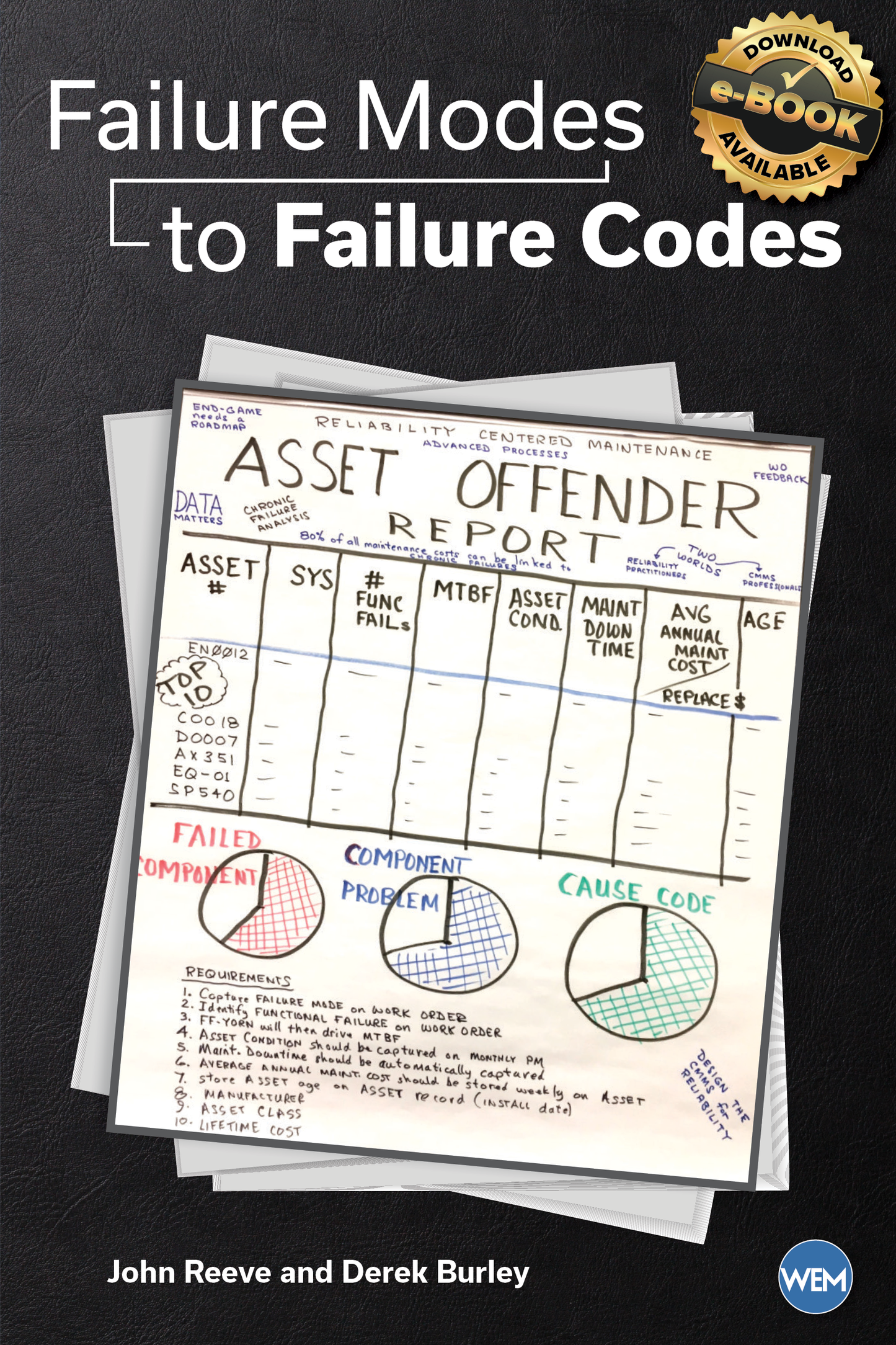

As an improvement initiative, chronic failure analysis may be the most significant benefit yet to be realized by the world of asset management. When stakeholders talk about the accuracy of their CMMS, they are really referring to the absence of good failure data. Consequently, when management requests any type of failure analysis, they are usually thinking of a verbal exercise and talking to people. They think this way because the work order only has text fields describing the problem and remedy. Without actionable data, there is no way to identify worst offenders in Pareto format. Failure Modes to Failure Codes explains exactly how to start capturing a true failure mode in support of RCM. All that’s required is the knowledge to configure the CMMS product.

Key points:

- If reliability centered maintenance is your goal, failure mode should be your centerpiece as this is the language of RCM.

- The asset offender report (failure analytic), once implemented, provides the reliability team the ability to identify worst offenders in multiple ways. And never assume this type of report will exist out of the (CMMS) box.

- As an improvement initiative, chronic failure analysis offers the largest potential benefit in support of return on asset (ROA).

About the Author - John Reeve and Derek Burley

John Reeve

John Reeve was the second consultant hired by the company that invented Maximo. He spent the first ten years as an international consultant in project management involving scheduling system and cost management design. Aerospace and defense indus-tries as well as nuclear power plant construction and operation depended on this soft-ware. In the following 20 years, his focus shifted to asset management design. During this time, he submitted a U.S. Patent in maintenance scheduling for an “order of fire” design. He can comfortably discuss advanced processes for both asset reliability and work force productivity. These combined field experiences plus certified reliability leader accreditation have created a framework from which to share valuable insight.

His credentials include 12,000 LinkedIn followers, 100 postings on industry best practices, numerous trade magazine articles, and this book, Failure Modes to Failure Codes. His combined knowledge in both project management and asset management make him unique in the consulting field. His goal is to bring the CMMS community closer to the world of RCM practitioners. Significant overseas assignments included Australian Defence Industry (Sydney), Australian Submarine Corporation (Adelaide), Pohang Steel (South Korea), and Power Generation Company of Trinidad.

Derek Burley CRL, CMRP, MIAM

Derek spent twenty years working in British Rail signaling as a control and systems engineer. In 1997, he moved to the United States, working as an Asset Management and RCM consultant across a wide range of industries: oil & gas (O&G), railroad, food, automobile, cement production, wastewater treatment, mining (copper and diamonds), and pharma and medical. In 2003, he joined Cargill and was engaged in establishing RCM training programs, facilitation certification, and standards development. In 2008, he moved to Rio Tinto as Principal Advisor—Maintenance Tactics Development, based in Salt Lake City, Utah.

Over the last 15 years, he has presented papers, articles, and workshops at numerous conferences on a variety of subjects including RCM, human error, change management, reliability engineering, asset management, and procedure based maintenance. He founded Blue Sky Reliability Consulting LLC in 2013. The company specializes in asset management and RCM training, facilitation services, and project support.

Contents

Chapter 1 - Fundamentals Aren’t Always Fundamental

Chapter 2 - Precision Maintenance Needs Precision Data

Chapter 3 - Viewpoints from the RCM Facilitator

Chapter 4 - Configuring the System

Chapter 5 - Effective Asset Management